Spain Shipping

5,1k

mal gelöst

Anfänger

Schwierigkeitsgrad

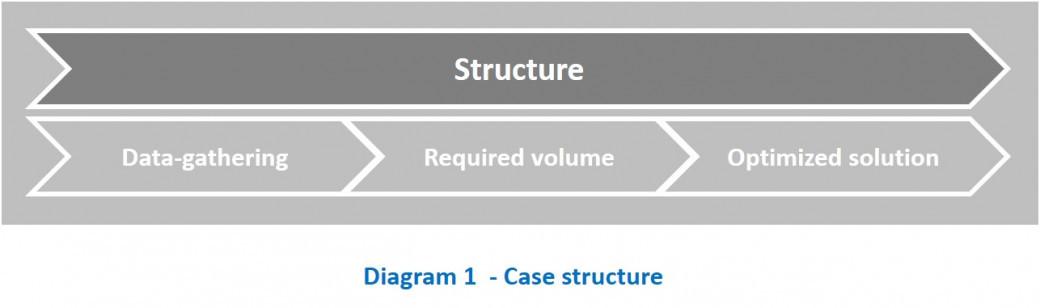

Our client is a local shipping firm in Spain where they handle local shipping of packages delivered by international shipping firms like FedEx, UPS & DHL. These firms deliver packages to the key city hubs and then our client takes it from there.

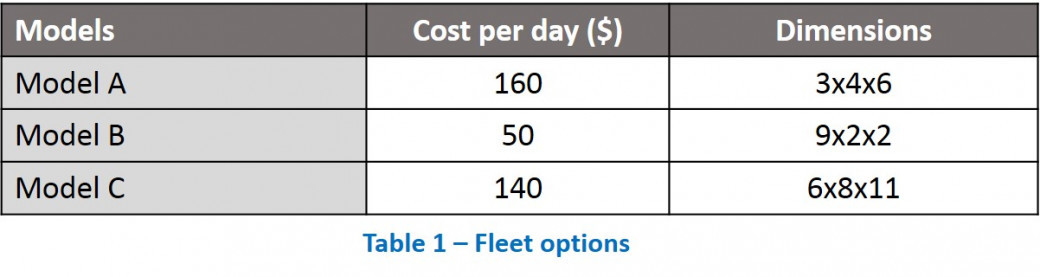

They want to know how many trucks they should lease to support their operations. From a cost-savings perspective they can only lease one model-type and we need to find out how many trucks the start-up needs.

Case-Kommentare

5,1k

mal gelöst

Anfänger

Schwierigkeitsgrad

Hast Du eine Frage zu diesem Case? Stelle sie der Community!