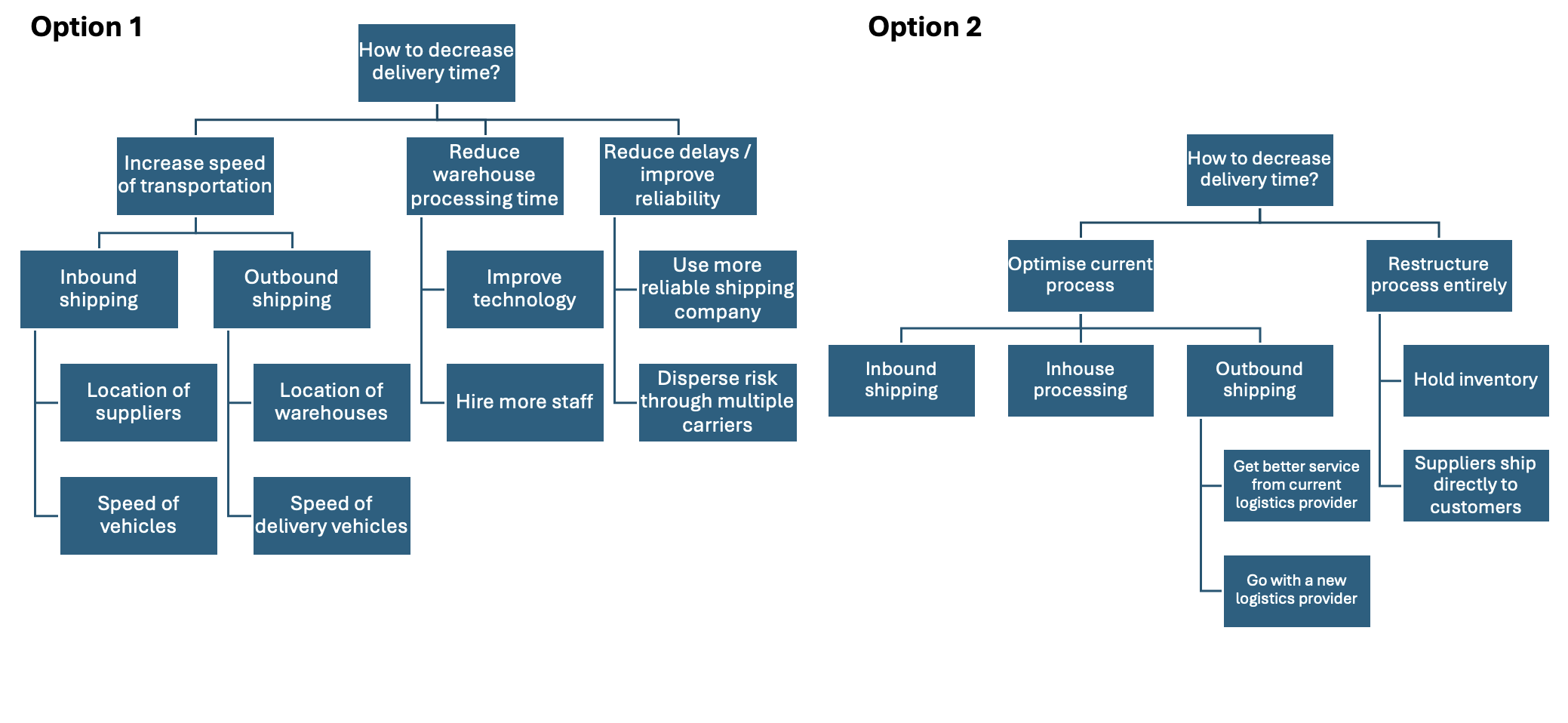

Hi everyone! I have just begun my case prep work, as I have a first round interview with an MBB firm scheduled end of the month (....I know I should have started earlier). I am now trying to figure out the best way to approach this whole framework thing, and am a bit puzzled; for some cases it makes a lot of sense to me what the obvious choice would be (e.g. profitability, market entry, M&A), whereas for others I am completely lost, like supply chain/operations cases. I have drawn up two frameworks to a case I tried on how a company can reduce delivery times in its shipping, and I was wondering if both were fine/one is better or worse. Overall, I'd just love feedback on what constitutes a good framework, and how to not feel like I am completely missing the point every time. Much appreciated!