Fast Dish, a publicly traded Quick Service Restaurant (Franchise) company with over €20 billion in revenue and more than 20.000 restaurants globally, has recently faced major challenges with regards to supply chain management and sustainability.

The client's top management has engaged the SCM and procurement specialized consultancy Inverto to advise the company in this critical situation.

Case Prompt:

Part I

An initial meeting with the CPO of Fast Dish will be conducted tomorrow. Fast Dish aims to discuss optimization potentials in the current collaboration with suppliers as well as levers to improve the supply chain resilience & carbon footprint.

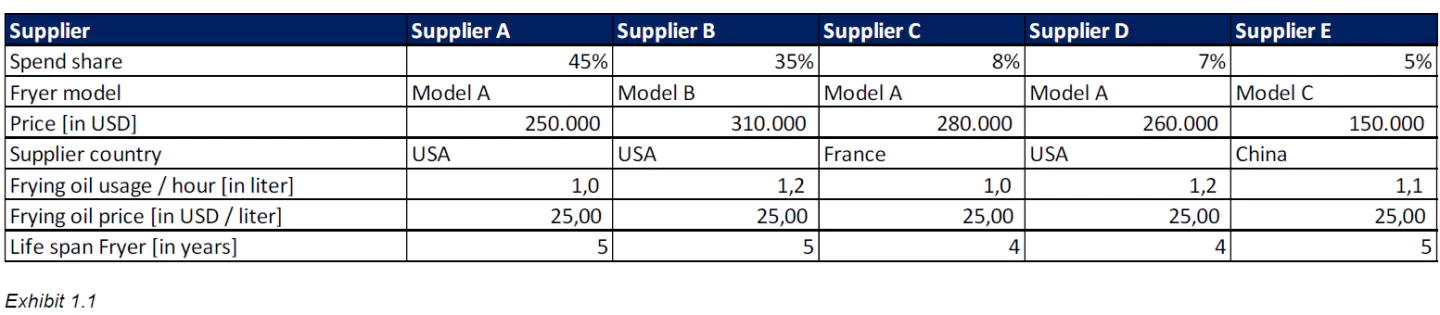

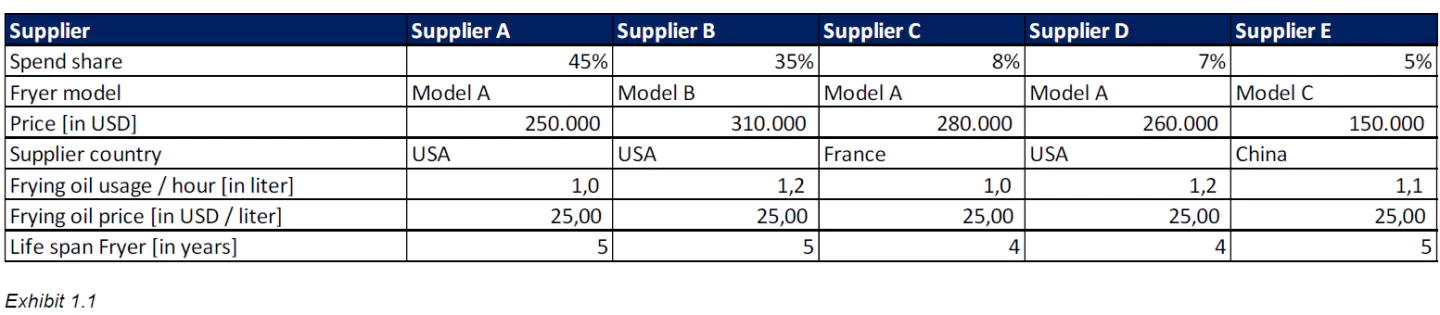

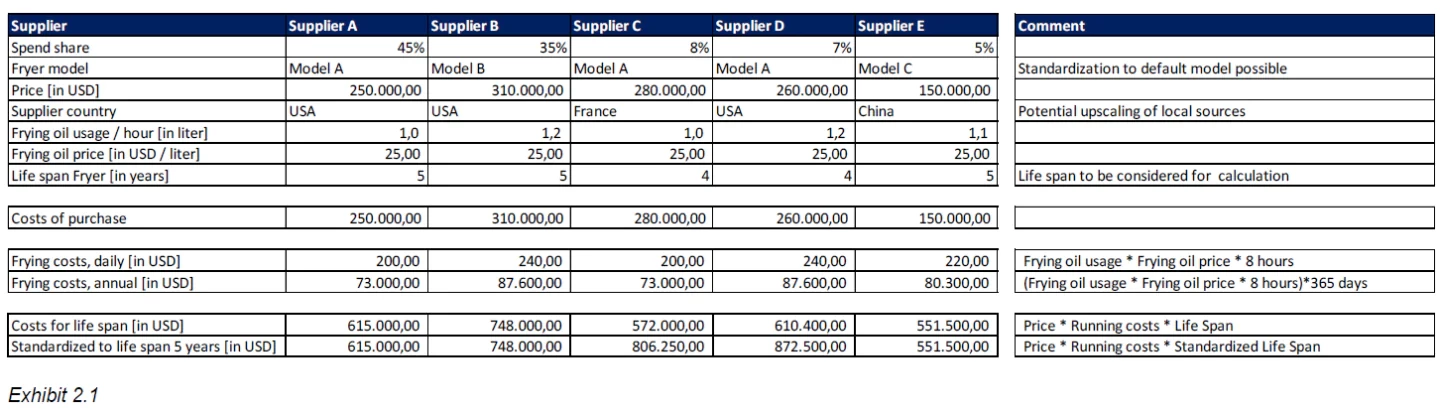

Unfortunately, Fast Dish has only submitted the following data for the sub-category ‘Fryers’ in the category ‘Core Kitchen Equipment’ yet. The top-5 suppliers count for 80% of the annual spend.

For the initial meeting with the CPO, your Project Manager asks you to evaluate savings potentials. Which procurement levers would you suggest to further investigate under consideration of Total Costs of Ownership (TCO) (Definition: an estimate of all the direct and indirect costs involved in acquiring and operating a product or system over its lifetime)? What are potential risks that might occur considering the current supplier landscape?

Handout exhibit 1.1

Additional information that can be shared on request:

- The current fryer models A, B & C have similar qualities & characteristics. The models can be substituted with each other.

- Please assume 8 hours usage / day for fryers.

- Further cost components such as energy consumption, maintenance, spare parts etc. do not need to be considered in this case setting.

- Read and understand task

- Calculate TCO (using exhibit 1)

- Use the data of TCO to identify the following facts:

- Supplier E as most competitive supplier

→ Bundle majority of current demands and assign to this supplier (e.g. 80% or depending on local coverage) - Supplier A as 2nd best supplier

→ Assign remaining demands

- Supplier E as most competitive supplier

- Use these facts to identify potential levers and risks named above and below:

- Standardization of models

→ Eliminate 2 out of 3 models, if supply continuity of remaining model is guaranteed - Outphasing of non-competitive suppliers

→ e.g. Supplier D with same model and origin as Supplier A but with higher costs)

- Standardization of models

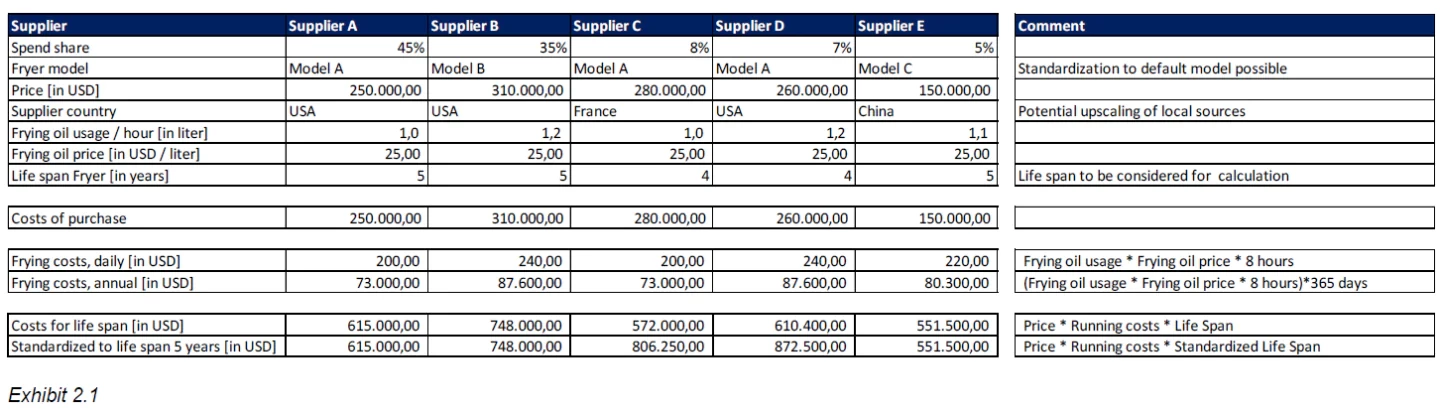

As shown in the table, Fast Dish currently purchases several Fryer models with different prices. Exemplary procurement levers, that should be further investigated, are bundled demands and product standardization.

Demand bundling (considering potential risks):

- Assignment of current demands to most competitive suppliers (commercially)

- Outphasing of non-competitive suppliers

Product standardization (considering potential risks):

- Definition of preferred Fryer out of models A, B & C and global standardization of usage over franchisees

- Outphasing of non-preferred Fryer

Potential risks that should considered can be the following:

- Supplier dependencies due to potential shift of demands to most-competitive supplier (negotiation power, supplier default risk, etc.) → 2nd source etc. should be considered in category strategy

- Product dependencies in case of solely one used model over franchise → Product substitutes shall be considered in category strategy

Part II

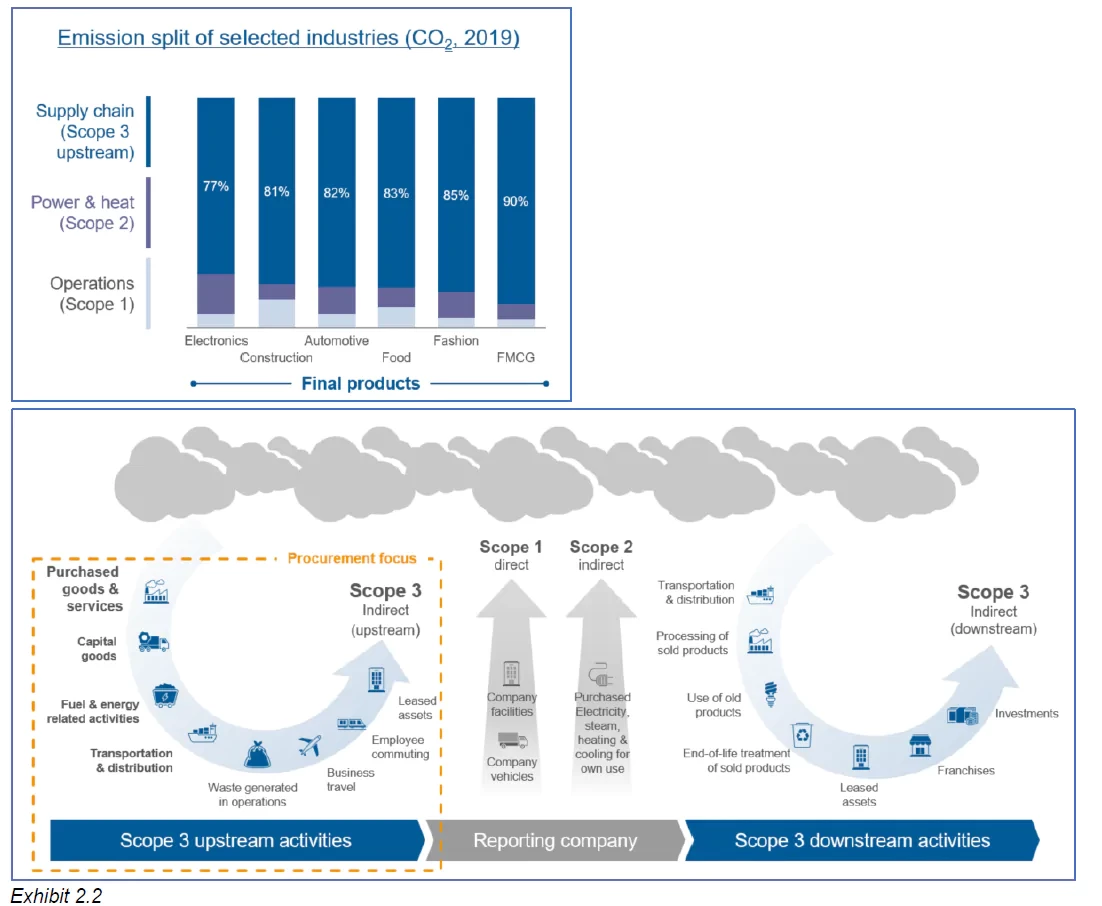

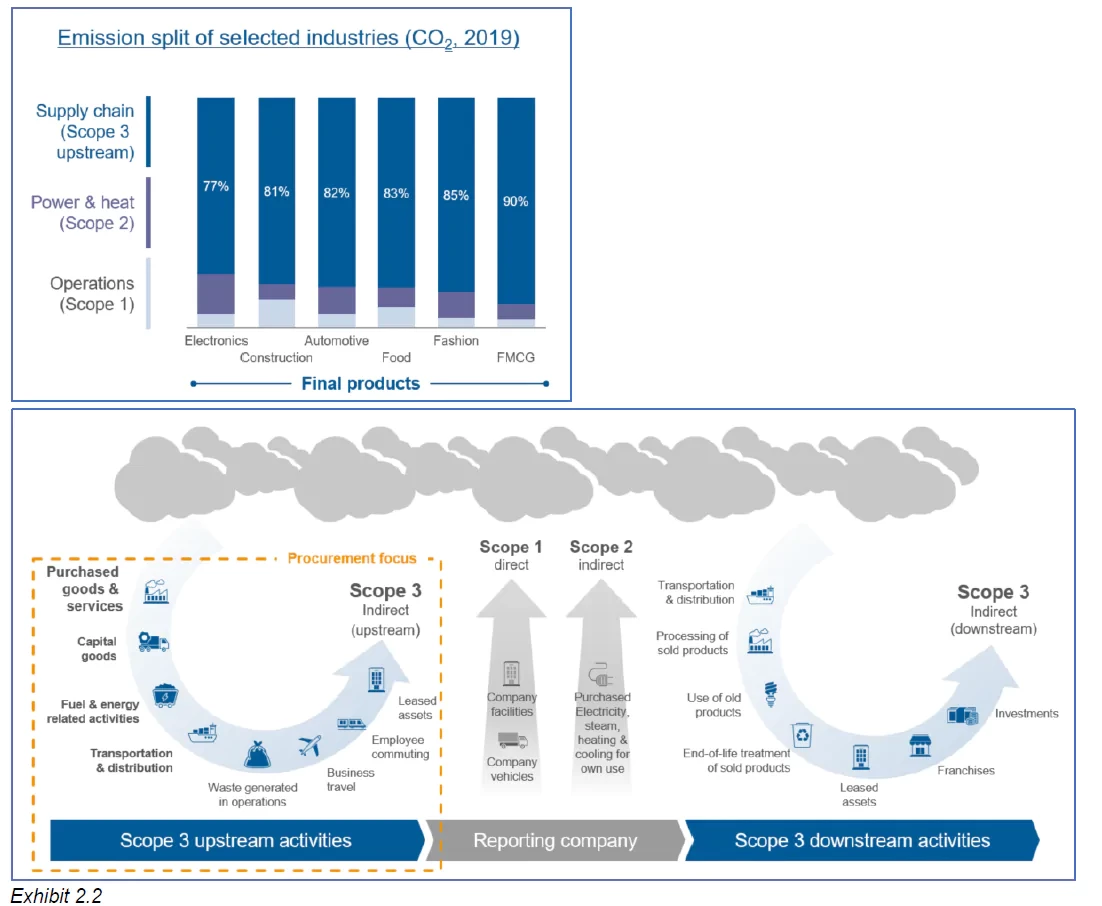

The CPO is enthused about the initial analysis and the saving potentials for ‘Fryers’. Nevertheless, he has doubts how to merge the optimization with Fast Dish’s ambition to reduce carbon emission by 50% by 2030 and to reach net-zero by 2050. In preparation, the CPO found the emission split data in a BCG report. Furthermore, a value chain emission definition is handed over to you. The CPO is curious about the impact of procurement on Fast Dish’s emissions and asks you to further explain how improvements in the supply chain (Scope 3 upstream) can support to reach the company’s carbon emission reduction goals. The CPO especially wants to know about changes of products, processes & organization in the sub-category of ‘Fryers’ that might lead to lower emissions.

Hand out exhibit 2.1 and 2.2

Additional information that can be shared on request:

- The relevant final product for Fast Dish is fast food

- Scope 1, 2 & 3 (downstream) are also considered in the category strategy, but not relevant for the initial analysis

- Read and understand the task.

- Realize that the information of the exhibits isn´t necesserily helpful for the solution

- Identify at least two bullet points per category and explain further as done below

Product:

- Material sourcing, for ‘Fryers’ e.g.: Material switch, reduction of virgin material, higher share of Electric Arch Furnace Route (100% scrap), carbon free smelting

- Demand reduction, for ‘Fryers’ e.g.: Usage of substitute products in the restaurants (oven, air fryer, etc.), reduction of CO2-heavy indirect material purchases, sustainable packaging (omission of unnecessary packaging layers)

- CO2 optimized design, for ‘Fryers’ e.g.: Share of recyclables / scrap, material substitution, product substitution

Processes:

- Logistics, for ‘Fryers’ e.g.: CO2 network optimization, Mode of transportation (avoid air cargo), usage of local sources, possibilities for compressed oil to reduce replenishment times

- Renewables, for ‘Fryers’ e.g.: Buying green energy (e.g. Energy Attribute Certificates) or production of green energy (e.g. PV contracting on roofs) for production facilities

- CO2 optimized manufacturing, for ‘Fryers’ e.g.: Processes optimization (e.g. usage of heat from production process), alternative processes (e.g. pressed parts instead welding)

Organization:

- Governance, for ‘Fryers’ e.g.:Introduction of company-wide code of conduct to ensure sustainability-oriented collaboration with suppliers

- Controlling the footprint, for ‘Fryers’ e.g.: Ambitious target setting with suppliers, constant progress tracking

- Stakeholder engagement, for ‘Fryers’ e.g.: Regular supplier & OEM communication, external target communication

The selection beneath covers the categories product, processes & organization and three potential procurement levers in the sub-category ‘Fryers’ in order to reduce the company’s carbon emission. The interviewee should be able to name at least 2 levers per category.

Product:

- Optimize material sourcing

- Challenge and reduce demands

- Optimize CO2 design materials

Processes:

- Optimize logistics network planning

- Use renewable energies

- Optimize manufacturing processes

Organization:

- Implement code of conduct

- Track and control carbon footprint/ set up governance

- Engage all relevant stakeholders

Part III

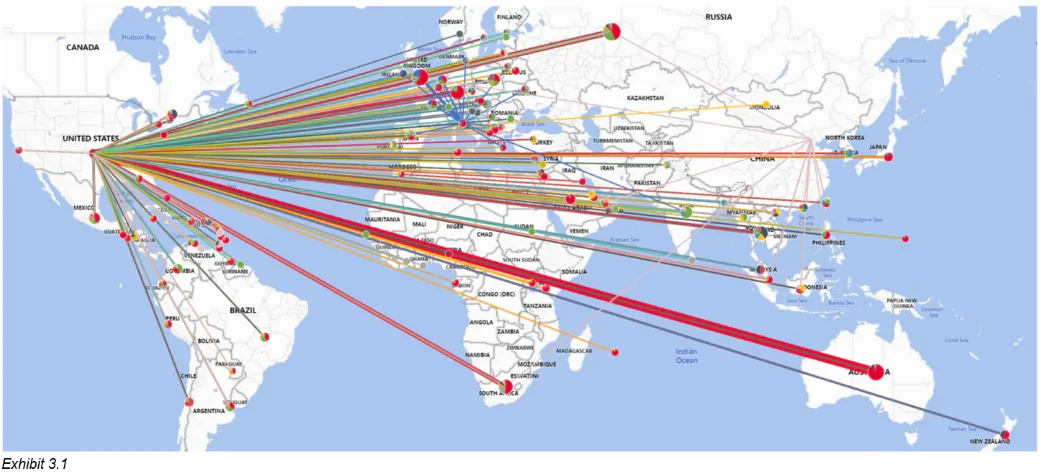

Besides reaching the carbon emission goals, Fast Dish aims to strengthen the supply chain by strategically maintaining its resilience since labor shortages, global freight delays and increased logistic costs are putting the market under pressure.

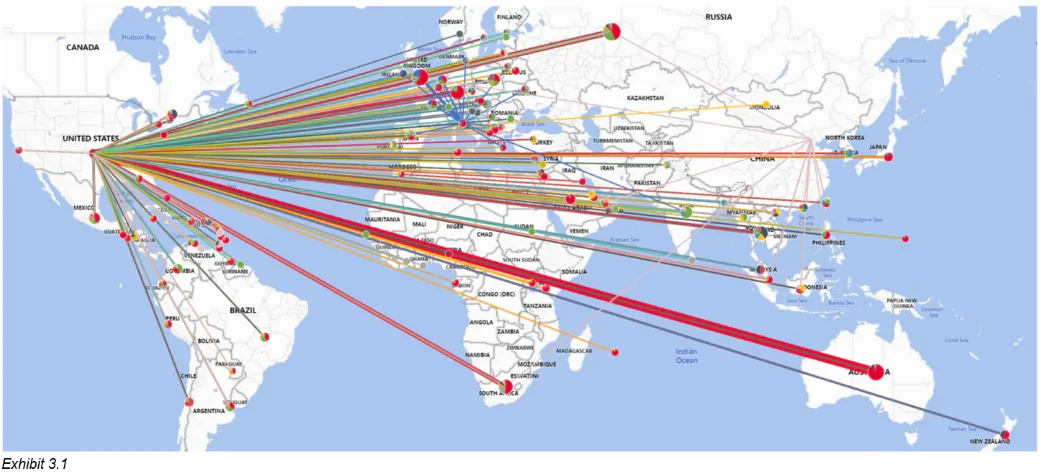

In order to further investigate the supply chain, Fast Dish provides you a general overview of the current spend by supplier, country of origin and destination for the commodity ‘Kitchen Equipment’.

The CPO wants to conduct a Request for Proposal (RfQ) and is keen to know about your approaches to mitigate supply chain risks while increasing ecological sustainability. As main targets of the RfQ, the CPO mentions the potential introduction of new suppliers and the establishment of strategic partnerships with incumbent suppliers.

You are being asked to come up with approaches that a) strengthen the entire supply chain resilience, b) improve the company's carbon footprint and c) address both - supply chain resiliance and sustainability - at the same time.

Handout exhibit 3.1

Additional information that can be shared on request:

- The US represents 87% of the spend for ‘Fryers’.

- Main markets for the company’s revenue are North America (24%), Europe (21%), Asia (18%), South America (15%), Australia (11%) and Africa (11%).

- Incumbent suppliers will participate in the RfQ.

- Fast Dish does not have any constraint with regard to suppliers origin and production country.

- Read and understand task.

- Identify the three subcategories and find at least two approaches that lead to the target.

- Explain approaches further.

The interviewee should be able to address several approaches that lead to the targets:

a) Supply Chain Resilience:

- Global approach of the tender in order to build up local sources

- Ask suppliers to consider all of their global locations & production facilities

- Challenge the business-continuity-management/ risk management of the supplier

b) Sustainability:

- Ask for sustainability strategy documents, e.g. certification of the supplier, e.g. DIN ISO 14001

- Challenge approaches of the supplier to reduce supply chain emissions (Tier-2, Tier-3)

- Include sustainability rating in RfQ evaluation process

c) Both:

- Selection of regional suppliers minimizes the risk of a supply default and, due to the shorter logistics routes, CO2 is saved.

- Selection of sustainable suppliers results in a better environmental footprint and reduces the risk of delivery failure through political influences

- Increasing the degree of digitalization makes the supply chain more secure and ensures that logistics resources are saved by improved planning

Part IV (optional)

Part IV does not count towards the 45 min case and can be solved if there is still time left.

The CPO received a request by a well-known german newspaper to participate in an interview. The interview topic refers to the geopolitical tension and how companies handle the increasing prices on the energy market. He hasn't had capacities to prepare for the interview, so he asks you to brainstorm potential approaches Fast Dish could take to mitigate the impact of increased energy prices.

- Read and understand Task

- Brainstorm on diffrent approaches

- Identify at least 5 useful approaches that reduce the usage of energy

- Explain why they reduce the usage of energy

Potential approaches for Fast Dish are:

- Adjustment of Fast Dish’s ‘Kitchen Equipment’ to eco-friendly setting (e.g. temperature of fryers etc.)

- Review of opening hours, delivery services, restaurant lighting, heating & air conditioning

- Conducting workshops with Fast Dish engineers and suppliers in order to develop carbon emission reduction approaches

- Establish company guidelines for sustainability incl. instructions for local management

- Training for employees to implement energy-reduction measurements in the restaurants

- Implement sustainability guidelines in company’s philosophy that also have a positive impact on energy usage, e.g., "refuse, reduce, reuse" principal:

> Refuse food waste (e.g. first in first out)

> Reduce useless lighting (e.g. restrooms)

> Reuse building materials (e.g. spare parts from discarded fryers)

Inverto Case: Fast Dish Restaurant