Our client is a start-up company that wants to mass-produce an electric vehicle for the US market.

So far it has developed a prototype all-electric vehicle.

They hired us to solve the problem of swapping to mass-production.

Our client is a start-up company that wants to mass-produce an electric vehicle for the US market.

So far it has developed a prototype all-electric vehicle.

They hired us to solve the problem of swapping to mass-production.

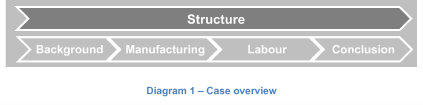

Information that should be shared with the interviewee (ONLY if asked):

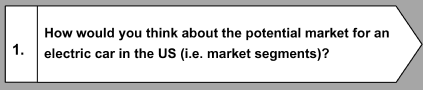

Breakdown customer segments

Price

Demand depends to a large extent on the price (price elasticity).

Range

The higher the range of the car, the more people will want to buy it (range anxiety).

Physical characteristics

Availability

The higher the availability throughout the country the more people will want to buy it. This is due to lower efforts in acquiring the car and in a higher presence of the car in different parts of the country.

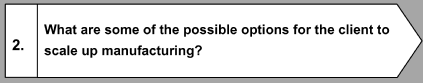

Own manufacture

Teslo could build its own manufacturing facility in the US or abroad.

US

+ Market car as American quality (higher perceived quality)

+ Low transport costs

+ Close proximity to suppliers

+ Possibility to get financial aid by American government

- Higher labour costs

- Actual quality may be lower (lack of skilled workers in US)

- Regulation of US government may be stricter

Abroad

+ Lower labor costs

+ Actual quality may be higher (lack of skilled workers in US)

+ Less strict regulation

- Higher transport costs

- Less proximity to suppliers (if from the US)

- Possible political issues, uncertainty about political stability

(depending on the country)

- Public reaction might be negative (production moved abroad)

- Perceived quality might be low (“Made in China”)

Outsourced manufacturing

Teslo could outsource the production to another company.

Besides the already mentioned Pros and Cons above, there are additional things to keep in mind.

US

+ Probably better/easier communication due to close proximity

+ Similar business culture

+ Easier on-time delivery (just in time)

+ Possible already established business contacts

- More difficult to set up the supply chain (spread over the country)

Abroad

+ Better supply chain (big factory regions in China)

- More difficult to communicate (especially face-to-face)

- Possible different business culture

- More complicated to deliver on time (just in time)

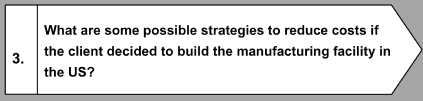

Automated manufacturing

+ High upfront costs (investment)

- Low variable costs (labor costs)

Labour intense manufacturing

+ High labor costs

- Low upfront costs

Choice of location

Different labor costs, taxes, subsidies, or transportation costs depend on the chosen location/state for the facility.

Engineering optimization

Reduce costs by reducing the number of steps needed in manufacturing or by limiting the possible vehicle customization (easier to produce in higher amounts and reach economies of scale).

Just in time delivery

Reduce storage costs with just-in-time delivery (easier in the US).

Production only on customer order

Reduce overproduction and storage costs by producing only for explicit customer orders.

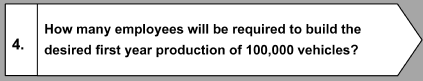

Now we can start with the more quantitative part of the case.

Information that should be shared with the interviewee (WITHOUT asking):

Information that should be shared with the interviewee (ONLY if asked):

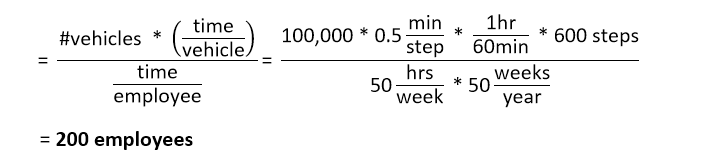

The expected needed number of employees is 200 (in the manufacturing process).

Main conclusion:

Other possibilities:

What problems could the company face in the new market sector of electric cars?

What problems could the company face in the new market sector of electric cars?

Possible solutions:

There is uncertainty about the demand. The production of 100,000 units could be either too high or too low depending on the demand. This could lead to unnecessary high storage costs for the remaining cars if the demand is lower than expected.

More questions to be added by you, interviewer!

At the end of the case, you will have the opportunity to suggest challenging questions about this case (to be asked for instance if the next interviewees solve the case very fast).

Electric Mobility

i