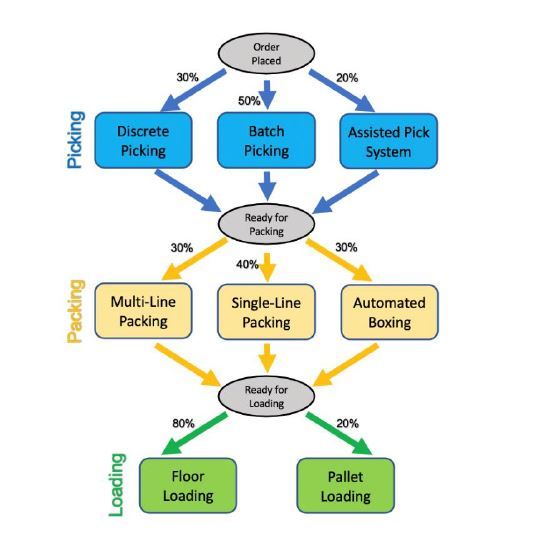

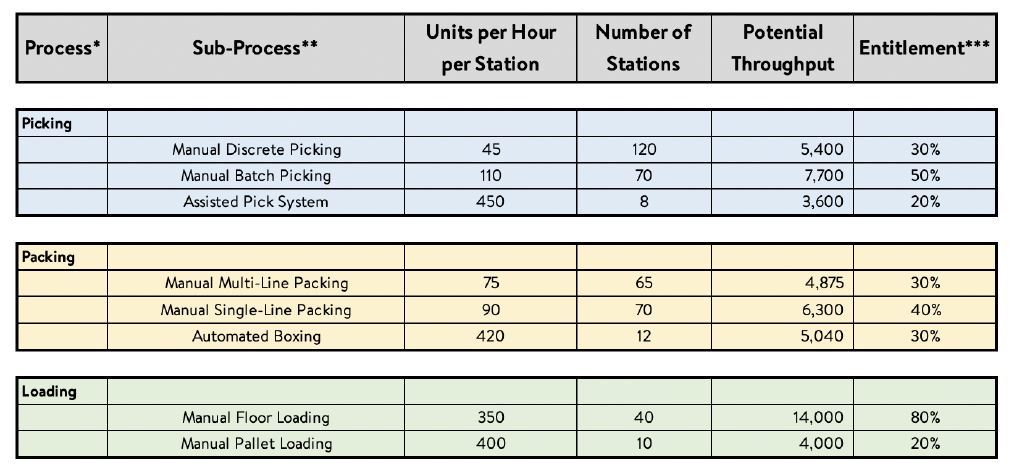

1)How would you approach analyzing the system and identifying a bottleneck?

2)What additional considerations or assumptions would you need to have in order to make a

recommendation on how to improve the system? What recommendations would you consider?