Your client is a German manufacturer of disguises for events and parties called KostümCo. They segment their products in two lines: round-the-year and seasonal products.

Round-the-year products serve customers that celebrate birthdays and common parties during the whole year.

Seasonal products aim at special occasions like the carnival or the beer festival in Munich and are only sold for some time before these events.

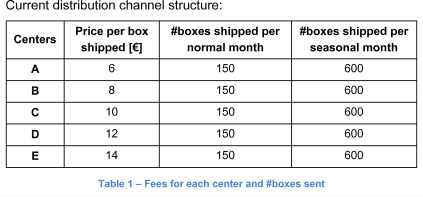

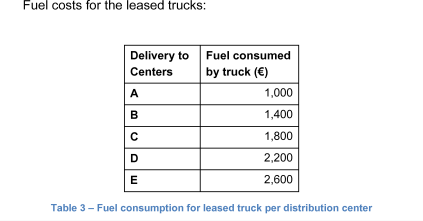

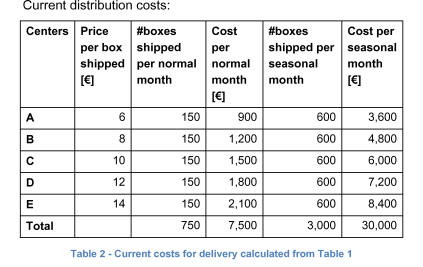

KostümCo makes the design, manufacturing and resells the disguises to retailers in 5 different German cities.

Recently, though, the largest retail customer complained that KostümCo’s prices are too high. After some internal analyses, the client found this to be due mainly to distribution costs. You have been asked to figure out how we can reduce distribution costs.

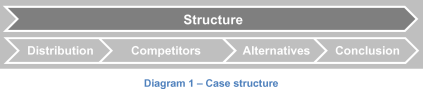

Disguise distribution

i